May 17, 2018 | News & Events

To celebrate an action-packed summer, Vokèra by Riello is launching its new Summer of Sport promotion for installers. Participants can redeem points to win sports-themed rewards such as store vouchers and football shirts, just in time to cheer for club or country. Vokèra is a leading manufacturer in quality home heating solutions, offering a comprehensive product range for domestic home heating and light commercial applications. Vokèra, through its parent company Riello Group, is a part of UTC Climate, Controls & Security, a unit of United Technologies Corp. (NYSE: UTX).

From the 1st May until 31st August, Vokera’s Affinity loyalty and reward programme members will receive points for every evolve or Vision combi or system gas boiler installed and registered. Multiples of three evolve or six Vision boilers will receive even more with bonus points.

Neil Mattock, marketing director at Vokèra, comments, “It’s great to be able to offer installers a new and exciting promotion for the summer. There is a great deal of sport ahead this summer, with World Cup football just around the corner. Installers can use their Affinity points against many sports-related items in a special area within the Affinity platform. This way, they’ll all have something to celebrate even if the football doesn’t go their way!”

The Vokèra Affinity is free to join and open to Gas Safe registered installers in the UK and Register of Gas Installers of Ireland (RGII) in the Republic of Ireland. By signing up for the programme, installers can register a Vokèra boiler for warranty, Gas Safe notification (UK only), and be awarded Affinity points on qualifying products. Any installers who are not currently members of the Vokèra Affinity programme gain 70 bonus points when signing up.

The state-of-the-art evolve combines Vokèra’s extensive knowledge of boiler design, performance and servicing to deliver a superior, cutting-edge boiler range. With both combi and system boilers, evolve suits a wide variety of domestic applications. The whole range is easy for installers to fit and homeowners to use.

The feature-rich Vokèra Vision combi and system boiler range is designed to be installer-friendly and suitable for a range of applications. Weighing between 27kg and 29kg, the Vision system and combi boilers are easy for installers to lift and fit into small spaces, such as a kitchen cupboard.

May 1, 2018 | News & Events

SOLUTIONS, PROMOTIONS & MORE AT INSTALLER 2018

Vokèra by Riello, will be showcasing its innovative range of domestic and commercial boilers including its ground-breaking evolve domestic gas boiler range at Installer2018. The Vokèra stand will also host some fun surprises with a competition you won’t want to miss! Installer2018 is at Ricoh Arena, Coventry, 8-10 May 2018.

“We’re delighted to be exhibiting at the Installer show again this year,” says Neil Mattock, Marketing Director at Vokèra. “The event is a great platform for us to demonstrate our products and we are looking forward to taking visitors through the evolve platform as well as our commercial heating solutions range. But it doesn’t end there. We will be launching our new Vokèra Affinity ‘Summer of Sport’ promotion as well as having some competitive fun on the stand. Make sure you pop by and say hello.”

Members of the Vokèra team will be on hand at the Installer2018 show to answer any questions or queries you have regarding Vokèra products or the industry.

Get to know evolve

The state-of-the-art evolve combines Vokèra’s extensive knowledge of boiler design, performance and servicing to deliver a superior, cutting-edge boiler range. With both combi and system boilers, evolve suits a wide variety of domestic applications. The whole range is easy for installers to fit and homeowners to use whilst also being extremely energy efficient. Visitors will also have the opportunity to see the evolve boiler with the BeSMART internet-connected thermostat. Vokèra’s new commercial heating products will also be on display in the UK for the first time.

Apr 3, 2018 | News & Events

From the 6th April 2018 the legislation around heating manufacture and installation in England is changing. Introduced by the Department for Business, Energy and Industrial Strategy (BEIS), the new Boiler Plus legislation will apply to retrofit and new installations in England only (new build is excluded).

Its objective is to raise standards of efficiency for domestic heating systems, to give consumers more choice over the way they heat their homes and to gain more control over their energy bills.

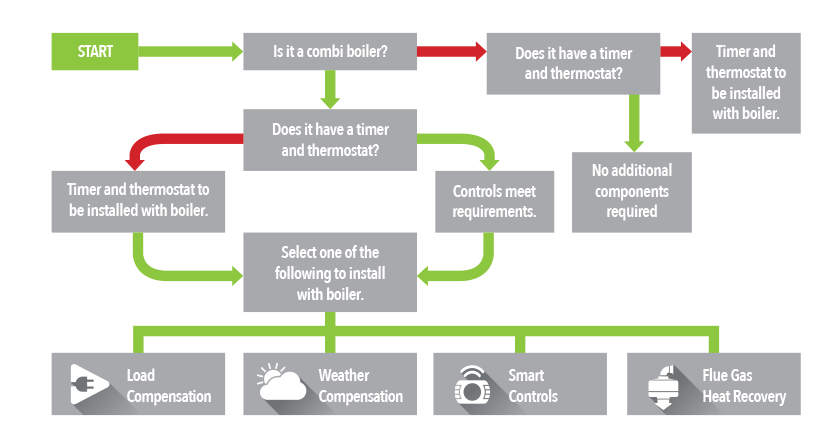

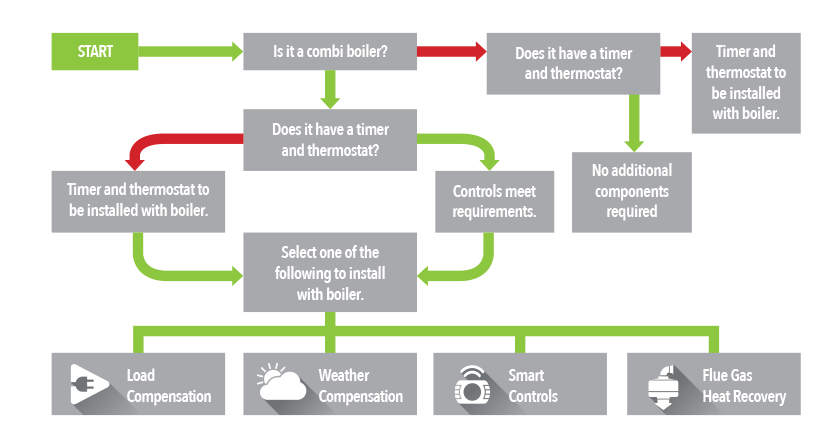

Boiler Plus requires a new minimum space heating efficiency for domestic gas boilers in English homes to be 92% as declared under the ErP Directive; whilst in addition, all boiler types must have time and temperature control. When installing a combination boiler, at least one of the four additional energy saving measures must be included:

- Load Compensation – lowers boiler operating temperatures thereby improving efficiency in line with internal demand whilst maintaining comfort levels.

- Weather Compensation – lowers boiler operating temperature in line with external air temperature whilst maintaining internal comfort levels. Air temperature can be drawn from an external sensor or internet derived.

- Smart Controls (with automation and optimisation) – automation is a control function that automatically adjusts time and temperature settings, based on occupancy detection and / or stored data from user adjustments over time. Optimisation is a control function which starts the boiler operation at the optimum time to achieve the set point temperature at the start of the occupancy period.

- Flue Gas Heat Recovery Systems (FGHRS) – recovering heat from waste flue gases to preheat domestic cold water entering the boiler, reducing energy needed to reach the required level for the domestic hot water.

Boiler Plus is a positive change and is definitely a step in the right direction in tackling climate change and keeping household energy costs down. The strategy aims to reduce carbon emissions across Europe, with the ultimate goal of achieving the EU’s 2020 targets.

Vokèra is here to help and can offer installers all four of the energy saving measures outlined within Boiler Plus, allowing consumers and installers alike to achieve compliance quickly and easily. For instance, the new evolve range, is A-rated and all models feature a space heating efficiency of 94% under the Energy-related Products (ErP) Directive. The Vokèra BeSmart Wi-Fi enabled thermostat offers automated home heating control and can be accessed via a smartphone, tablet or desktop computer. The majority of Vokèra’s boilers also come with pre-configured weather compensating technology and are OpenTherm enabled to help maximise efficiency.

For more information on Boiler Plus click here

Feb 23, 2018 | News & Events

Calling all Installers…. don’t miss out on the final months of Vokèra’s evolve Promotion, valid until 31st March 2018.

The promotion celebrates the launch of the evolve boiler range and rewards Vokèra Affinity members for installing and registering evolve boilers.

When installing the evolve range, Vokèra Affinity members will receive a fuel card worth £1001 upon completion of their first installation registered via the Vokèra Affinity loyalty and reward programme. A £502 fuel card will then be issued for each subsequent installation registered via Affinity. Alongside the fuel cards, installers are also able to offer an extended warranty on the evolve, taking it from a standard seven year warranty to an impressive ten years, when installed with a BeSMART internet-connected thermostat and both the evolve and BeSMART registered on Vokèra Affinity.

The state-of-the-art evolve from Vokèra combines extensive knowledge of boiler design, performance and servicing to deliver a superior, cutting-edge boiler range. With both combi and system boilers, evolve suits a wide variety of domestic applications. The whole range boasts an A rating and all models feature a space heating efficiency of 94% under the Energy-related Products (ErP) Directive. With the addition to the system of Vokèra’s BeSMART internet-connected thermostat, with weather compensation enabled, the evolve range offers the potential to become an A+ heating package under ErP.

Vokèra Affinity focusses on giving unparalleled support and rewards to installers and has grown to become one of the heating industry’s most enduring loyalty programmes. It has also recently benefitted from further improvements and developments to make the platform even better. By signing-up for the scheme, installers can register a Vokèra boiler for warranty and register for their Affinity points. Vokèra Affinity also provides installers with additional benefits such as marketing support, information on products, spare parts, stockists, literature and technical support on the move.

For more information on the range as well as news and updates, visit or follow Vokèra on: Facebook | Twitter | LinkedIn.

Jan 15, 2018 | News & Events

Vokèra by Riello, a leading heating manufacturer, is thrilled to be nominated in the Domestic Heating Product of the Year – Boilers/Water Heaters category at this year’s prestigious H&V News Awards.

Vokèra has been recognised for its new state-of-the-art evolve, a cutting-edge boiler range that has been born out of the company’s extensive knowledge of boiler design, performance and servicing. With both combi and system boilers, evolve suits a wide variety of domestic applications. The whole range boasts an A rating and all models feature a space heating efficiency of 94% under the Energy-related Products (ErP) Directive. With the addition to the system of Vokèra’s BeSMART internet-connected thermostat, with weather compensation enabled, the evolve range offers the potential to become an A+ heating package under ErP.

“It is a real honour to be a finalist for the H&V News Awards,” says Neil Mattock, Marketing Director at Vokèra. “The H&V News Awards represents the best in the industry, there are some great finalists and we are delighted to be amongst them. When we launched evolve last year, we were confident that we had developed a great boiler platform. The feedback we have received from our customers has been great but to be nominated for an H&V News Award as well is a fantastic achievement.”

As the longest-running award ceremony within the industry and now in its 24th year, the H&V News Awards have a fantastic reputation for celebrating and rewarding excellence across the building services industry. This includes anyone from contractors and consultants, installers, private building owners, service and maintenance companies, building information modelling (BIM), retrofit and safety and training providers. This year, the awards will take place on 19th April 2018 at the Grosvenor House Hotel in London.

For more information on the range as well as news and updates, visit or follow Vokèra on: Facebook | Twitter | LinkedIn.

Jan 10, 2018 | News & Events

We are delighted to announce the appointments of Scott Foster and Martin Fletcher as Commercial Sales Managers for the North and South respectively.

Scott and Martin are working as part of the team headed up by Sales Director, Peter Diamant with the aim to support and grow the Vokèra by Riello, Commercial brand with new and existing customers across the U.K.

“We are extremely pleased to welcome Scott and Martin to the team,” says Peter. “Our commercial division is growing all the time and we are delighted with the feedback we have received from customers about our commercial solutions. Both Scott and Martin will support our growth aspirations and we look forward to the energy and enthusiasm they can bring to the organisation. They are both experienced industry professionals having previously held roles in a number of companies across the commercial sector.”

For news and updates, visit www.vokera.co.uk or follow Vokèra on: Facebook | Twitter | LinkedIn