Nov 26, 2019 | News & Events

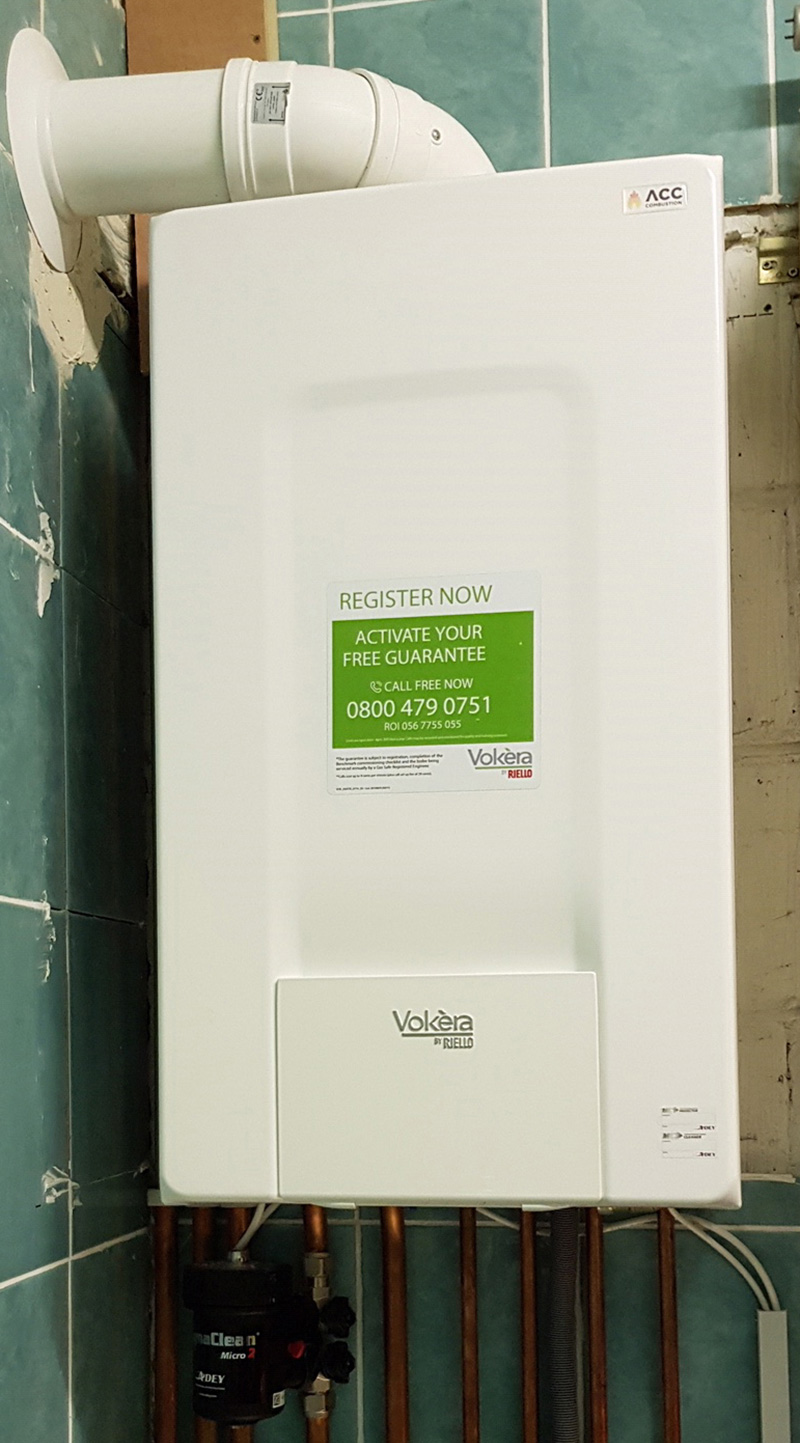

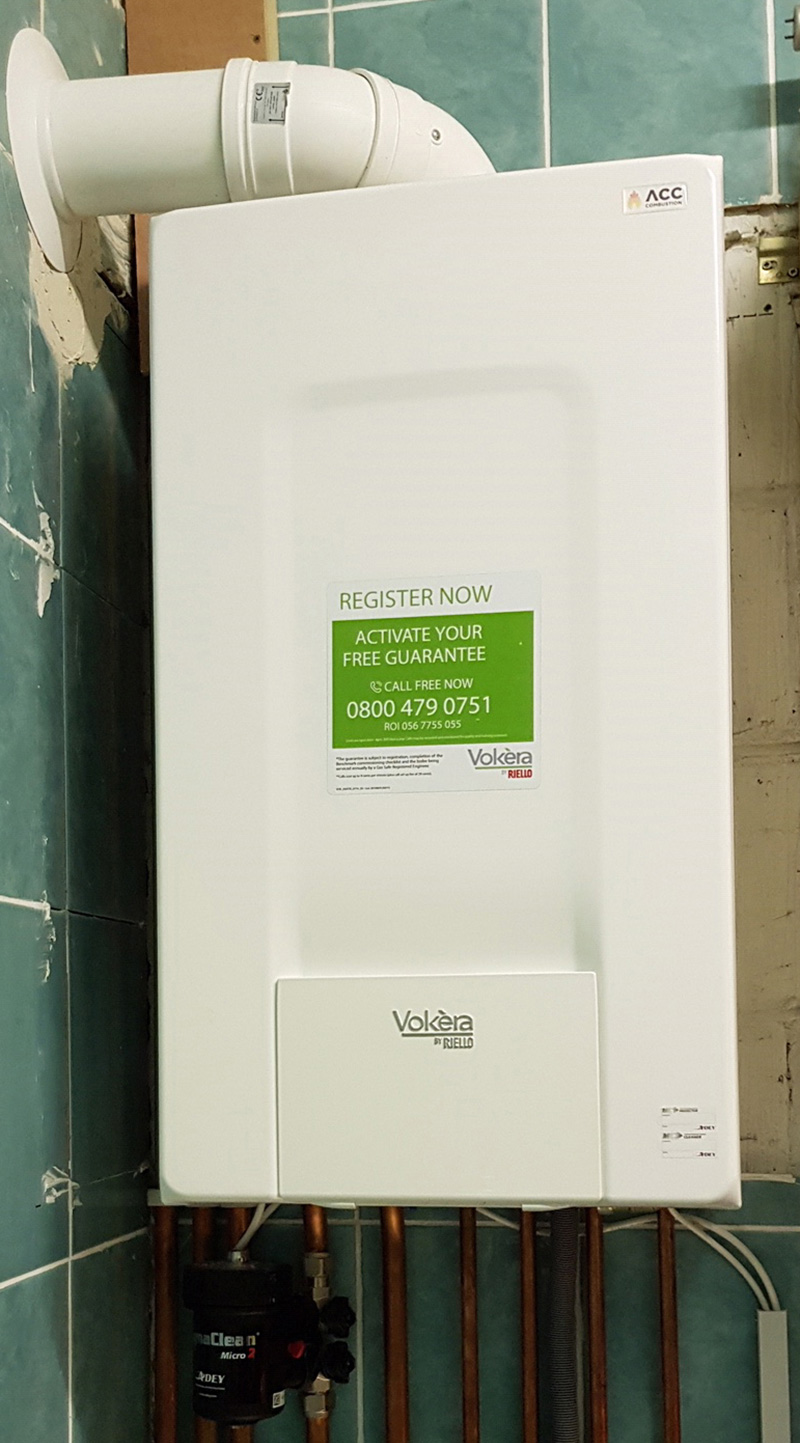

Vokèra by Riello donated one of its technologically advanced combi boilers for a local Scout Group building project in Scotland. The high-efficiency Vokèra evolve 36C (36kW) gas condensing combi will be installed by East Ayrshire Council’s heating and plumbing apprentices, giving them valuable hands-on experience under professional supervision, all while assisting a worthwhile community programme. Vokèra will also provide commissioning support to the apprentices and on-site training by one of its highly-qualified technical teams. Vokèra, through its parent company Riello Group, is a part of Carrier, a leading global provider of innovative heating, ventilating and air conditioning (HVAC), refrigeration, fire, security and building automation technologies.

“Vokèra is one of our most valued and trusted partners when it comes to providing reliable new and replacement boilers for our social housing tenants,” said Barrie Mclatchie, project officer for East Ayrshire Council. “We install around 850 of their appliances every year and their support and training are always excellent. We believe their efforts will have lasting community benefits and ensure the viability of a building that combines warmth and efficiency for this important local youth facility.”

According to Apprenticeship Statistics for England* there were 23,000 apprentices in the Construction, Planning and Built Environment sector in 2017/18. The Scout Hall project reflects Vokèra’s commitment to supporting local community initiatives and helping to create the next generation of highly skilled heating engineers by offering professional training and support.

“In addition to training for individual installers, we also assist colleges, councils and housing associations with high-quality training for their students and staff,” said Neil Mattock, marketing director for Vokèra. “We have established more than a dozen affiliations with education facilities that offer plumbing and heating courses, providing them equipment and other resources for their training departments. And this support has now been extended to allow other colleges to send their students for courses at our well-equipped training centres.”

The Vokèra evolve 36C gas condensing combi boiler will be at the heart of a complete new heating system for the Scout Hall and will be connected to approximately 10 radiators. Offering warmth, comfort, energy efficiency and superb performance, the evolve 36C is ideally suited to meet the building’s heating and hot water demands.

*Apprenticeship Statistics: England: February 2019: House of Commons Library research service.

Oct 9, 2019 | News & Events

Some might say that heating installers have never had it so good with the wide range of products from which to select and assemble a system that meets or even exceeds their customers’ needs and wants (or disappoints). David Iszchak, Technical Trainer at Vokèra by Riello looks at the basics of boiler efficiency in keeping homeowners comfortably warm at an affordable cost.

If the average homeowner does any research when considering a new boiler then it will probably be restricted to information from a brand they’ve heard of or whatever turns up on an internet search. They may often be more attracted by the presentation of a product, or the appearance of a control than the capability or potential of the appliance, or just as importantly, the appliance and control combined. Achieving comfort with energy efficiency at low cost is generally what most homeowners desire, but how are these three desires reconciled in a real world installation?

Certification efficiencies

Boiler efficiency is hard to assess as ‘test bench’ figures may not be representative of how a boiler will actually work in a property. Steady state test bed operation at two flow and return temperatures (80-60°C and 50-30°C) allow manufacturers to extrapolate test efficiencies of over 100% which, if the case is warm, the flue is warm, or there is water vapour at the terminal, could be mislead. These figures are steady state testing on certified test rigs and heating systems simply do not work in that way. The thermal performance of properties will also differ greatly depending on factors such as location and lifestyle: weather patterns are not consistent; occupation patterns vary, as do heat gains from solar, cooking and electrical appliances.

Reality Bites: The closest a real world system is likely to get to steady state testing is to be operated continuously at temperatures that do not allow the boiler to cycle on/off. For the majority of the heating season the maximum output of the boiler is not required (this is certainly the case with a combination boiler) so good modulation between maximum and minimum output to the heating system is important. Generally speaking, 1:5 is thought of as a minimum and a higher turndown ratio will improve matters if it does not entail too much additional cost or complication. So, keeping the boiler on longer seems to suggest this might bring the boiler closer to certification efficiencies, but at what cost? Running longer does not necessarily mean more fuel will be used as a boiler with a wide modulation range will be able to match output to the varying load of the property. However, during low load operation heat is still lost from the appliance through the flue. If the boiler cannot modulate down to meet the load then it will cycle off and on however if cyclical losses are low continual losses through the flue may exceed pre and post purge inefficiencies and standby losses. Range rating the boiler heating output to the likely maximum requirement of the property, particularly with combination boilers, is a simple way to reduce cyclical losses and boiler firing cycles.

Squaring the circle

Is there any way the boiler efficiency can be improved further? Well, yes there is, because we know condensing boiler efficiency is better with some heat exchangers if operated at lower temperatures to encourage harvesting of latent heat. This will require the type of control that can adjust the boiler flow temperature in line with system demand rather than simply turning the appliance on or off and operating up to a preset maximum temperature. Here the control is being integrated with the appliance and we introduce what I call a system efficiency which adds to the appliance efficiency. If the heating control adjusts the boiler in order it runs cooler and at condensing temperatures more often than the boiler efficiency will improve but will the efficiency gain be eroded by prolonged run time losses?

Advise responsibly

Whatever the type of boiler or control, comfort is the primary objective for most households but acceptable levels of comfort differ. Also, whilst an end-user’s preference may be 23⁰C if their budget only covers heating the house to 19⁰C then how can that circle be squared? It is often quoted that a 1⁰C reduction of the space heating setpoint is the equivalent of 8% saving in fuel for heating. If this is to be believed then a 3⁰C reduction should equate to a 24% reduction in the fuel cost –really? Almost a quarter?

Perhaps the most important thing to remember is that the homeowner is the one paying the fuel bill not the installer so any advice or claims on energy savings must be given responsibly. I know this may come under the heading of ‘stating the obvious’ to the reader of a trade magazine however, to use a phrase from the education sector, it’s also what’s known as ‘reinforcement.’ Sometimes the object of the exercise becomes hidden behind an avalanche of marketing information trumpeting worst to best case scenarios when that is rarely the case the installer is faced with. The object of the exercise is customer satisfaction with an installation and running cost they can afford that will win the installer the work and retain the customer; the homeowner is not a test bed for the latest marketed technological advance.

Finally, it is important not to lose sight of the absolute basics when it comes to optimising boiler and system efficiency:

- The boiler efficiency is the baseline, everything else is an incremental improvement to system efficiency.

- Running the space heating to a warmer air temperature will cost more – check the thermostat setting to see if it could be dropped a degree without compromising comfort and dress according to weather conditions.

- Running it longer will cost more – check if adjustments could be made to the time schedule.

- Running it too cool will cut costs but could mean discomfort – try not to adjust the thermostat too much, let it do its job.

- Not running the heating long enough may be a false economy and can lead to damp and mould in the house – don’t allow the property to become too cool and encourage condensation when unoccupied.

- Automatic adjustment of the boiler flow temperature to lower levels improves the efficiency of a condensing boiler – consider a control type that can adjust boiler temperature.

- Turning the heating up from a phone before arriving home could cost more than waiting till you get home; if the house contents are at a stable economy temperature during unoccupied periods it will not take long to warm the air.

- Turning the heating off may appear to save fuel but may cost more with the energy needed to reheat the property from an ambient temperature – heating the air only is quicker than heating the air, walls, furniture that have grown cold.

- Setting two levels, an occupied (comfort) level and an absence (economy) level is a good compromise – consider a control that offers choice of both time and temperatures.

- Firing the boiler is what costs the money – controls that regulate a space without interacting with the boiler are not as effective as devices that can – basic thermostatic radiator valves do not directly interact with the boiler and are often poorly positioned.

- A space heating control in one area is better than none at all – some sort of time/space heating boiler interlock is a mandatory requirement.

- A space heating control that can assimilate heat requirements from several areas, keep them at varying temperatures and control the boiler firing is better still – consider aggregated multi-zoning if the budget allows.

- A control that can adjust the boiler operating temperature while achieving the above is even better still – this will encourage condensing operation at the boiler.

- If the boiler is in a position that is difficult for the user to access, then a control that allows the user to monitor and adjust the boiler operation as well as control the heating at the room thermostat, phone or app is better still – the homeowner can monitor its operating condition from the room thermostat or internet connected device.

- Training is key to help installers understand the capabilities of what type of boiler and control is fitted. One of the most critical elements in the whole process is the installer’s ability to explain the control in a simple and concise manner avoiding confusion or repetition and encourage customers to use the controls for optimum heating efficiency and comfort.

Sep 17, 2019 | News & Events

Vokèra by Riello launches AquaNova LE, a simple and energy-efficient solution for providing instantaneous domestic hot water to multiple outlets at a high flow rate. With low nitrogen oxides emissions, this new addition is classified under the Ecodesign of Energy-related Product Directive (ErP) Class A, making it fully compliant with the latest ErP Tier 3 requirements. It is ideal for domestic and small, light commercial applications that require an instant and reliable hot water supply, such as restaurants and shops. Vokèra, through its parent company Riello Group, is a part of Carrier, a leading global provider of innovative heating, ventilating and air conditioning (HVAC), refrigeration, fire, security and building automation technologies.

“Easy to install and to service and featuring a powerful heat output, our new AquaNova LE offers a continuous supply of hot water, and can be used simultaneously at various outlets while delivering a high flow-rate,” says Alister Maclachlan, product director, Vokèra. “In addition, this compact water heater takes up less space than a conventional storage tank and virtually eliminates standby losses as energy isn’t wasted when hot water cools down in long pipe runs or while it’s sitting in the tank.”

Delivering a flow rate of 13.2 litres per minute at temperature rise of 35 degrees C, AquaNova LE can fit applications where space is at a premium. Continuous gas modulation and electronic temperature sensing ensure accurate temperature control for user safety and comfort. A temperature lock function can be used to limit the outlet temperature, while a keypad lock function prevents tampering. The appliance features a digital display and user interface for ease of operation and there is also a fault code display function for diagnostic purposes. For increased efficiency, the appliance’s electronic ignition eliminates the need for a constantly running fan or energy-wasteful pilot light.

AquaNova LE is available in natural gas and liquefied petroleum gas (LPG) versions and is also designed to accept pre-heated water for solar integration. Installation and commissioning are simple with all connections easily accessible and a built-in fly lead. The appliance is designed for flexible flueing and can be flued horizontally or vertically using Vokèra’s concentric uni-flue or twin-flue systems. Units also include stand-off brackets required for rear outlet flue exit. Servicing has also been simplified as there is no diaphragm or water section, which reduces maintenance requirements.

Summing up this latest innovation, Maclachlan, says: “When new ErP efficiency requirements for water heaters came into effect in September 2018, many existing appliances no longer complied. AquaNova LE has been specifically developed to provide a compliant solution that combines high performance with ease of installation, and is backed by our two-year warranty.”

For more information on AquaNova LE, please visit www.vokera.co.uk/trade-professionals/water-heaters.

Sep 1, 2019 | News & Events

Since the introduction of condensing technology, boilers have continued to increase in efficiency, with most current appliances able to reach over 90% efficiency. Neil Mattock, marketing director at leading heating manufacturer, Vokèra by Riello looks at how the correct use of control can further enhance boiler efficiency and performance without compromising comfort.

The technology within boilers is now so advanced that, even with future developments, there seems little chance of boiler efficiency percentages increasing much beyond current levels. This being the case, other ways are needed to maximise energy and fuel savings for the sake of both the planet and hard-stretched household budgets. One solution is the use of heating controls which, when correctly installed and used, can optimise comfort and economy for end-users. Modern central heating controls provide homeowners with the flexibility to have the boiler on at different times of the day and at different temperatures. Some devices can even sense the temperature automatically and adjust the boiler operation, while an Internet connected smart thermostat offers the added convenience of controlling the home temperature remotely via a tablet, smartphone or desktop computer.

Boiler Plus

The energy saving potential of high efficiency heating controls was recognised in Boiler Plus, new standards for domestic heating that came into force in England in April 2018. This latest legislation is aimed at giving consumers more choice over the way they heat their homes and more control over their energy bills. Boiler Plus set a new minimum space heating efficiency of 92% under the Energy-related Products (ErP) Directive for domestic gas boilers in English homes. As already mentioned, most of today’s condensing gas boilers already achieve this minimum – in fact, all models in Vokèra’s A-rated evolve range feature a space heating efficiency of 94% under ErP.

As part of its remit to help consumers cut their energy bills, Boiler Plus also requires an additional energy saving measure when fitting a new combination boiler. The options are to install a flue gas heat recovery system, which may not always be practical, or one of a choice of controls, namely weather compensation, load compensation, or smart controls featuring automation and optimisation functions.

Weather compensation interacts intelligently with the boiler to reduce the heating flow temperature, which increases efficiency without compromising user comfort. Indeed, the average efficiencies in a condensing boiler can be increased by an extra 2% with the simple addition of a weather compensation control. The load compensation option measures the gap between what the internal temperature is and what the user wants it to be, and modulates the boiler so that it only uses as much fuel as necessary to close the gap.

Intelligent choice

In addition to ensuring compliance where applicable, installers face a potentially confusing choice of controls to meet their customers’ particular requirements and budgets. There are controls that can be used with combi and system boilers that include basic time clocks, there are basic room thermostats, programmable room thermostats, and so-called ‘intelligent’ options that incorporate the most advanced technology available, such as weather compensation.

Over the past few years, forward-thinking boiler manufacturers like Vokèra have developed a comprehensive range of innovative appliances and control devices to help reduce the amount of fuel used by boilers to heat a home. For example, the majority of our domestic boilers now come with a pre-configured weather compensating function and are OpenTherm protocol enabled to help maximise efficiency. In essence, OpenTherm takes over the management of the heating flow temperature and raises or lowers the flow temperature from the boiler in order to maintain the desired room temperature. When used in conjunction with an external weather compensation sensor the flow temperature to the heating system increases as the outside temperature drops: if the external temperature rises, the heating flow temperature lowers accordingly. Combining the sensor with an OpenTherm programmable room thermostat will ensure the internal target temperature is maintained within the property.

Get smart

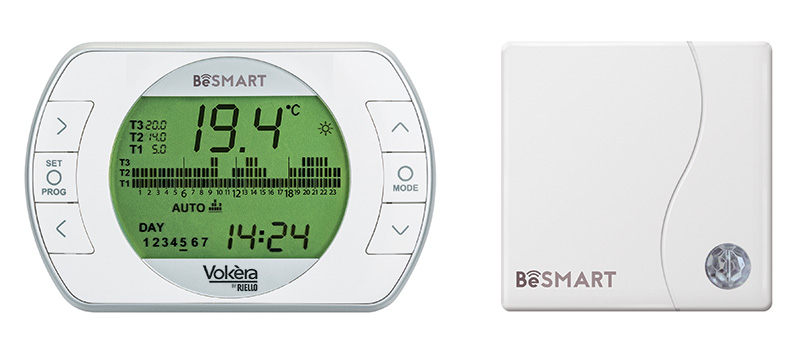

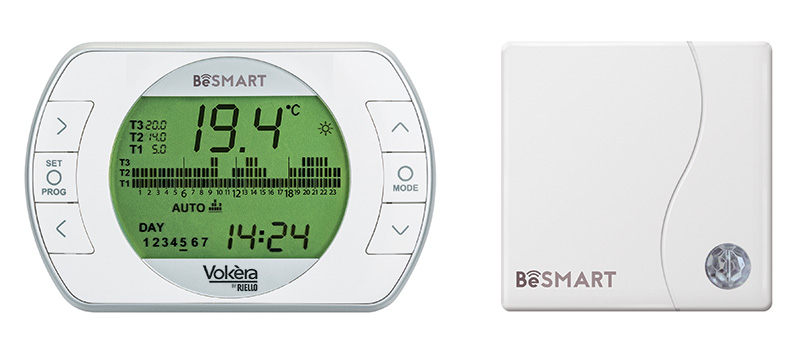

From our experience, smart heating controls don’t come much smarter, or simpler to install than BeSMART. Although designed to complement the Vokèra boiler range, this versatile control will also work with most high efficiency domestic boilers with On/Off control, making it an ideal replacement for old thermostats. BeSMART can be set-up for single or multi-zone control, with an impressive eight-zone maximum. The BeSMART App is available on both iOS and Android and works on a smartphone or tablet. Users can adjust the temperature, programme in settings and even check the boiler operating conditions, providing them with new levels of control over their heating system.

Take control

When it comes to heating their homes, consumers are bound to be attracted to controls that combine ease-of-use and affordability with additional energy efficiencies that won’t compromise comfort. It’s no surprise, therefore, that smart heating controls incorporating features such as automation, optimisation, and weather compensation using local weather data via the web, are an increasingly popular way for many homeowners to keep their houses comfortably and affordably warm. As the market continues to move towards smarter heating, we believe astute installers should embrace this sophisticated yet simple to use control technology for the benefit of their customers and their business.

Aug 30, 2019 | News & Events

Given the advanced technology and sophisticated electronics in modern gas condensing boilers it’s not surprising that even the most experienced Gas Safe engineer needs to seek expert advice from time to time. Whether you are a trade professional or an end-user, Eric Brawley, Technical Coordinator at Vokèra by Riello, offers a few tips on getting the most out of a technical support call.

Be prepared

Our UK technical team handles around 250 calls a day and always aims to answer enquiries as quickly as possible because we know everyone’s time is precious. We receive calls on a broad range of subjects, from flues and smart controls to spare parts and compliance. Whilst not every question is answerable in one conversation, callers can assist the process by being prepared. Before making the call, it helps to have some key information about the boiler to hand and, if possible, to be at the appliance. For example, a fault code showing on the boiler is one of the most common reasons for contacting our team. When this occurs, the first thing we need to do is determine the exact model of boiler we are dealing with. When you consider that Vokèra has produced over 200 different models, you can see the problem! The model details will be on the installation or user manuals, so it saves time to have these ready. If these documents are not available, we will point the caller to the section on our website where they can be downloaded.

An increasingly frequent question our team has to deal with these days relates to boiler controls. This could be a new product, or maybe a new tenant who is using the boiler for the first time. Again, it is worth finding out the precise model of control before calling as it could be a third-party device chosen by the installer. If it is not a Vokèra product we may be unable to override the device and will therefore need to direct the caller to the control manufacturer.

We also get many calls from Gas Safe engineers who need advice on repairs. Having confirmed the model we will ask a series of questions about what the boiler is (or is not) doing when it is trying to operate. Unfortunately, from our experience there is a 50% chance that the engineer is not alongside the boiler at the time. This can make answering our questions more tricky unless the caller has made detailed notes of the problem. Once we have the engineer’s feedback we can try and identify why the fault may have occurred and explain a systematic procedure to effect a repair.

Boiler siting

Boiler siting is a frequent topic tackled by our technical team and may require a site visit for more unusual installations. One of my most recent visits was to assess a Police Stables conversion in Glasgow. Work had to be halted after bones were found on site but, thankfully, it turned out to be a horse and not a human skeleton!

A common site visit will involve the replacement of old balanced flue water heaters with new high efficiency models such as the Vokèra AquaNova le. These installations have to comply with a zonal system for the siting of the heater. Our products are suitable for zones outside of zone 2 in this type of system, which would not have existed when the original appliance was fitted.

Site visits can be a challenge and may require compromises along the way. For example, I recently got a call from an engineer looking to replace a water heater that was currently under a worktop. I checked the size to ensure clearances could be met but unfortunately they couldn’t so an alternative site had to be found for the new appliance.

Flueing

Since Gas Safe issued a bulletin at the start of 2019 regarding verification that an unusual flue installation complies with the manufacturer’s instructions, we are being asked almost every day for confirmation on installations. To do this we require the attending engineer to supply us with some photographs of the installation, together with the address and the dimensions. If it has been installed correctly, we will keep a record of the communication from the engineer so no one is in doubt that it is compliant.

On the subject of flueing, our team is asked on a daily basis about how to connect a new boiler to an existing flue system, most commonly twin flue. Although we always look at the individual system and advise appropriately, from experience we generally advise against trying to connect to an old flue (15 or 20+ years). In view of the 80/125mm flueing options on modern HE appliances we tend to recommend a new flue system that is more suited to today’s appliances, fitted with the correct runs.

Boiler Plus

Another frequent question will be about Boiler Plus compliance in England, particularly with regard to controls, both in terms of what engineers need to do to comply and wiring. Needless to say, it saves time if the engineer has a basic understanding of the compliant options before calling. Our team can then go through the solutions from the cheapest to more sophisticated control in the OpenTherm configuration, for example, with the further option of remote Internet access for additional control if required. As the engineer seeking this advice is probably not at the appliance at this point, we can discuss any wiring questions once they have chosen their control and are at the boiler.

Indeed, enquiries about how to wire controls, particularly to ensure compliance, are very common. Whilst we can obviously advise on the products we have to offer and how these are wired to the boiler being fitted, in some circumstances the installer may be seeking generic advice on zoned systems and how they are incorporated into the boiler, as well as third-party devices. In this situation we can tell the installer, or more commonly the electrician, how they are wired into the boiler, but placing emphasis on the fact that the device must be used in a volt free configuration, or our relay will need to be used, to offer a 240V fitting option.

Specification

In addition to offering advice on boiler installations and maintenance, our team also receives calls from specifiers who are looking to figure out which model of boiler will best meet the needs of a particular project. In order for us to offer advice on this the specifier will need to provide some key project details such as the application, heat output requirement, and budget. We often refer specifiers to the Vokèra Product Guide that can be download from our website that shows boiler specifications in relation to inputs, flue lengths, water flow rates etc. Indeed, the advice being sought about a product specification, installation or servicing could be available at the click of a mouse, so it is well worth checking a manufacturer’s website or YouTube videos before picking up the phone.

The introduction of new products and constantly evolving technology can be an initial challenge for heating professionals and their customers. It is important, therefore, for them to know that there is someone at the other end of a phone to provide advice and answer any questions. By following a few simple tips before making a call our technical team will be better able to resolve an enquiry quickly and efficiently.

Aug 1, 2019 | News & Events

Leading heating manufacturer Vokèra by Riello has opened a new showroom in the training centre at its head office in London Colney. The venue showcasing Vokèra’s new and existing products for both the commercial and domestic heating sectors provides an ideal space for meetings and presentations. Vokèra, through its parent company Riello Group, is a part of Carrier, a leading global provider of innovative heating, ventilating and air conditioning (HVAC), refrigeration, fire, security and building automation technologies.

Vokèra’s addition to the existing training facility, which offers specialist training courses for installers and continuing professional development (CPD) training courses for specifiers, reflects the ongoing commitment to supporting its customer base.

“The showroom really enhances London Colney’s main product training centre for heating installers and specifiers,” said Neil Mattock, marketing director and head of training at Vokèra. “Whether you are a local community or commercial installer, college, plumber’s merchant or domestic installer, you can visit our London Colney centre to see our latest products and talk to our experienced team about the issues that affect your business and the wider industry.”

To contact Vokèra’s training department, call 01727 744002 or email [email protected].